How To Change Bellows On Omc Cobra

[8] 1. Remove oil level indicator plug and install lifting eye until full thread engagement is achieved.

-

Use a suitable hoist to remove vertical drive from holding fixture.

-

Remove and clean gasket material from pivot housing and upper gear housing.

[9] 4. Apply OMC Gasket Sealing Compound to both sides of a new gasket.

[10] 5. Inspect molded rubber seal ring J for proper fit in its groove. If damaged, replace it. Install pivot housing gasket H. Lightly lubricate large seal lip I with OMC Triple-Guard grease.

[11] 6. Slide alignment tool K through driveshaft gimbal bearing L. The alignment tool must slide through the bearing and into engine coupler with ease. If the alignment tool binds going into engine coupler, the bearing and/or engine must be repositioned until alignment tool slides in and out of engine coupler with ease.

[10] 7. Shift remote control of boat into neutral position. Apply OMC Triple-Guard grease to shift lever pin M.

[12] 8. Lubricate driveshaft splines with OMC Triple-Guard grease.

[13] 9. Lightly lubricate the two O-rings N of driveshaft with Evinrude or Johnson Outboard Lubricant or OMC Premium 4-Cycle Motor Oil. Excessive grease in O-ring grooves can hydraulically lock O-rings and cause difficulty starting driveshaft into gimbal bearing.

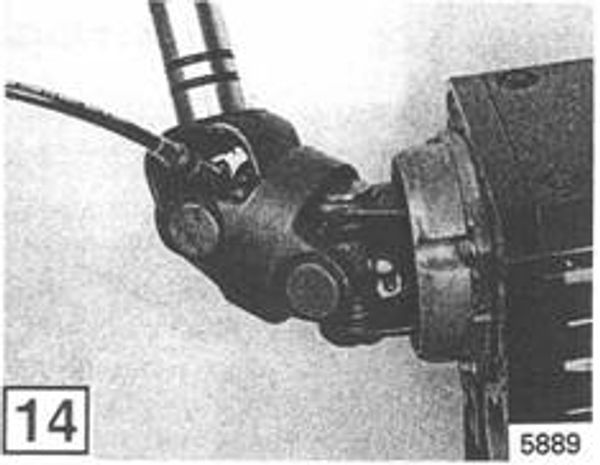

[14] 10. Grease both U-joints with OMC Marine Wheel Bearing Grease.

[15] 11. Lubricate outer surface of the universal coupler A with OMC Triple-Guard grease.

[16] 12. Apply a light coat of OMC Triple-Guard grease to tapered end B of bearing carrier.

[17] 13. Move vertiqal drive shift rod into neutral position. Propeller shaft should turn freely in both directions.

[18] 14. Apply OMC Gasket Sealing Compound to the six studs.

[19] 15. Slide driveshaft C into U-joint bellows and through gimbal bearing.

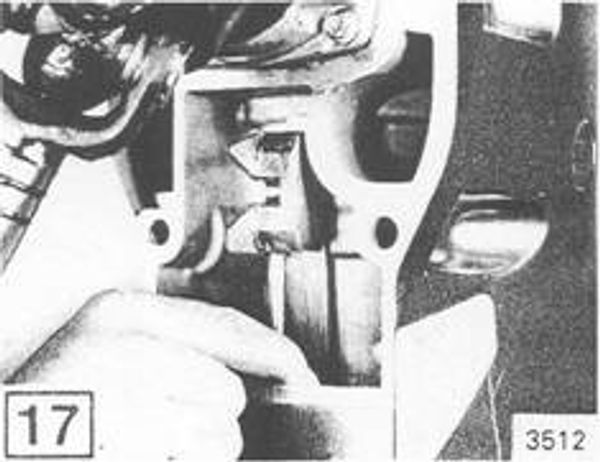

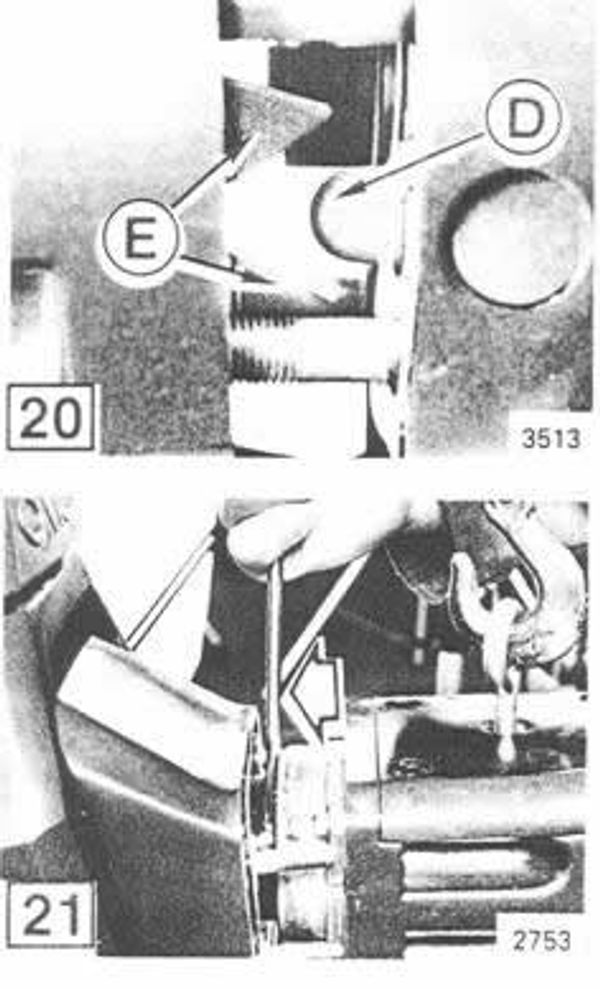

[20] 16. Check alignment of pivot housing sHift lever pin D and fork connector E of vertical drive to ensure they will mesh properly.

[21] 17. To align the driveshaft splines, use a long screwdriver or 1/4 in. diameter bar to turn universal coupler until the driveshaft splines engage the engine coupler. Slide vertical drive onto studs until completely seated against gasket of transom bracket.

- Install six flat washers and six new elastic locknuts.

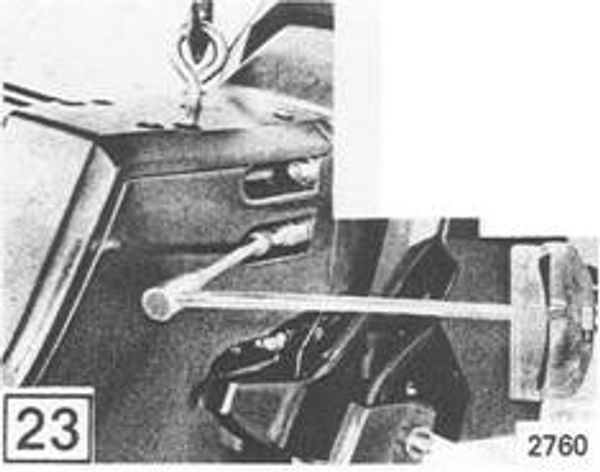

[23] 19. Use a 3/8 in. drive 5/8 in. swivel socket to tighten nuts to an initial torque of 25 ft. Ibs. (24 N'm). Start with the center nut and work in a crisscross pattern, as shown.

- Use the same crisscross pattern to tighten all six elastic locknuts to a final torque of 50 ft. Ibs. (68 N'm).

[24] 21. Apply OMC Triple-Guard grease to the trim/tilt pivot rod.

[25] 22. Align hydraulic arm bushings F with upper housing boss. Install trim/tilt pivot rod and spacer G.

Note: Use care when installing trim/tilt pivot rod or bushings can be damaged.

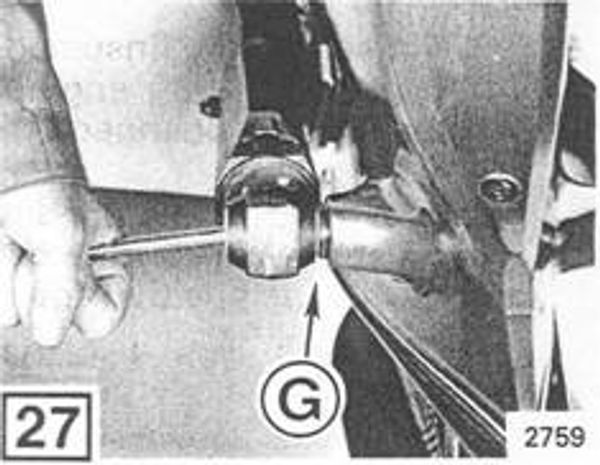

[27] 23. Align second hydraulic arm bushings with upper housing boss. A 3/8 in. bar can be used to turn rod end and align the bushings. Install a spacer G between the boss and rod end.

-

Pushing or pulling the lower gearcase will also help align the bushings with the boss.

-

Use a soft hammer to lightly tap trim/tilt pivot rod until shoulder of rod is equal on both sides of the hydraulic arms.

[30] 26. Apply OMC Gasket Sealing Compound to threaded end of pivot rod.

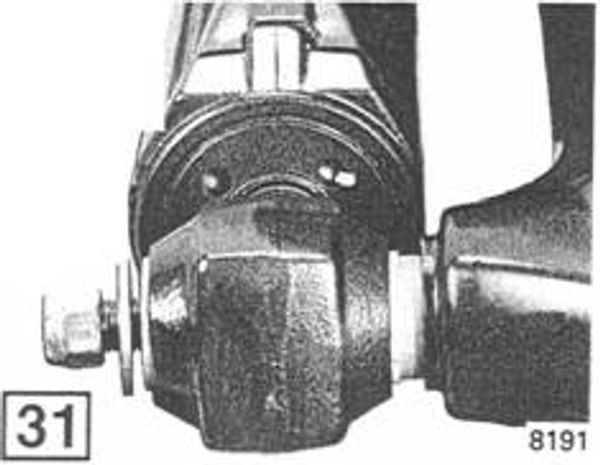

[31] 27. Install large flat washer H and elastic locknut I onto each end of pivot rod.

[32] 28. Hold one locknut with a 5/8 in. box end wrench. Tighten both locknuts until locknuts and washers bottom out on shoulders of pivot rod. Tighten to a torque of 32-34 ft. Ibs. (43-46 N'm).

- Remove lifting eye bolt from upper housing. Install oil level indicator plug using a new seal, and tighten to a torque of 48-72 in. Ibs. (5-8 N.m).

0317201 - OMC FL *GSKT SEAL 16OZ

0508298 - OMC TRIPLE GUARD 8 OZ

0775595 - OMC OIL-COBRA SD QT

0775619 - OMC BRG GREASE,3PK RPL

How To Change Bellows On Omc Cobra

Source: https://www.crowleymarine.com/d/tech_article/omc-cobra-complete-outdrive-installation

Posted by: flahertywifearmas.blogspot.com

0 Response to "How To Change Bellows On Omc Cobra"

Post a Comment